What Can a Cobot Do for You?

Cobots have revolutionised the manufacturing industry, improving the efficiency, safety, and quality of countless processes. They are helping SMEs to increase their efficiencies and productivity through strength, power, precision, and data.

Automation within manufacturing allows cobots to take care of the dirty, dull, and dangerous jobs so workers' time can be better placed on higher-value tasks. Using cobots throughout a factory allows any gaps in production due to labour shortages to be filled instantly. They also allow SMEs to remain competitive in challenging markets by taking on high-mix low-volume manufacturing.

While more businesses are realising the potential of cobots, some are still hesitant about their usage potential. With industrial robots fixed solely to one application, a single collaborative robot can be used across multiple areas of production. Cobots are an all in one complete automation solution that can be deployed to a wide variety of tasks, delivering precision on repetitive processes.

End of Arm Tooling (EOAT)

For SMEs, the fact that cobots can be used across multiple areas of production is one of their biggest assets. One of the core components responsible for the versatility of cobots is EOAT.

With a range of tooling, from grippers to vacuums, torque sensors and tool changers, cobots provide greater flexibility to solve labour shortages or increase productivity in the production line. Thanks to EOAT, collaborative robots can be used for a wide range of applications.

Machine Tending

Currently, many machine tending tasks are still performed by humans, which requires them to stand for long hours in front of a machine and tend to its operational needs. Maintaining the machine and loading the raw parts then removing the machine parts is a long and tiresome process for human operators. It is also becoming increasingly difficult to find workers to fill these types of roles. Machine tending is a poor use of an operators’ time when they could be focusing on detailed, highly skilled work that only a human can do.

CoboTend has the ability to undertake a wide range of tasks, from CNC, press brakes, manually loading and unloading components, and much more. As long as the supply of raw materials remains constant, CoboTend will load and unload parts for as long as you require. It can also work across multiple machines to increase productivity and production. Additionally, with cobots granting companies lights-out manufacturing, they can generate higher output and provide businesses with greater flexibility.

Pick and Place

Pick and Place applications are one of the best places to look when first looking to integrate cobots. The highly repetitive and mundane nature of these tasks can often lead to mistakes or injury from the physical demands of the job. Be it a packaging function or a sort function from a tray or conveyor, cobots can perform these tasks to a high level of accuracy. For cobots working on pick and place applications, EOATs are a great advantage. With grippers and vacuum effectors, they are able to adapt and grasp a range of objections to bring flexibility to manufacturers.

Excepting humans to work consistently with endless energy on pick and place jobs is unreasonable. They will become fatigued both physically and mentally, resulting in errors. With cobots undertaking monotonous picking and placing tasks, operators can be reallocated to higher-value tasks. This leads to greater job satisfaction, in turn contributing to lower staff turnover. Worker safety is also significantly improved as they no longer need to undertake labour intensive roles thanks to cobots.

Palletising

Palletising is another key area where cobots can make a great impact. The repetitive and physically taxing task of stacking boxes on pallets can be particularly dangerous for workers, especially when handling heavy and even hazardous items. Palletising can easily lead to injuries and loss of product stock due to human error.

Cobots allow palletising to be done more effectively and efficiently through automation. With the correct EOAT, boxes are picked up and stacked on pallets in a desired pattern to help maximise the amount of cargo and reduce any chance of toppling. With cobots allowing production to continue 24 hours a day, they can help to reduce the cycle time of a stacked pallet.

Welding

Welding is a skilled area where tasks must be performed with the utmost precision. As advancements in cobot technology lead to more sophisticated and sensitive systems, a range of welding tasks are now able to be automated. Mig/Mag, Tig, spot, arc, ultrasonic, laser, and plasma welding are all possible with CoboWeld, to deliver consistent outputs and ultimately reduce material wastage. Cobots ability to quickly switch to new welding tasks makes them ideal for series production in small numbers.

While cobots are capable of a range of weld types, it is important to remember that they are no replacement for highly skilled welders. Welding cobots, like CoboWeld, simply take on the repetitive tasks while human welders tackle more challenging, lower-volume projects that require their expertise.

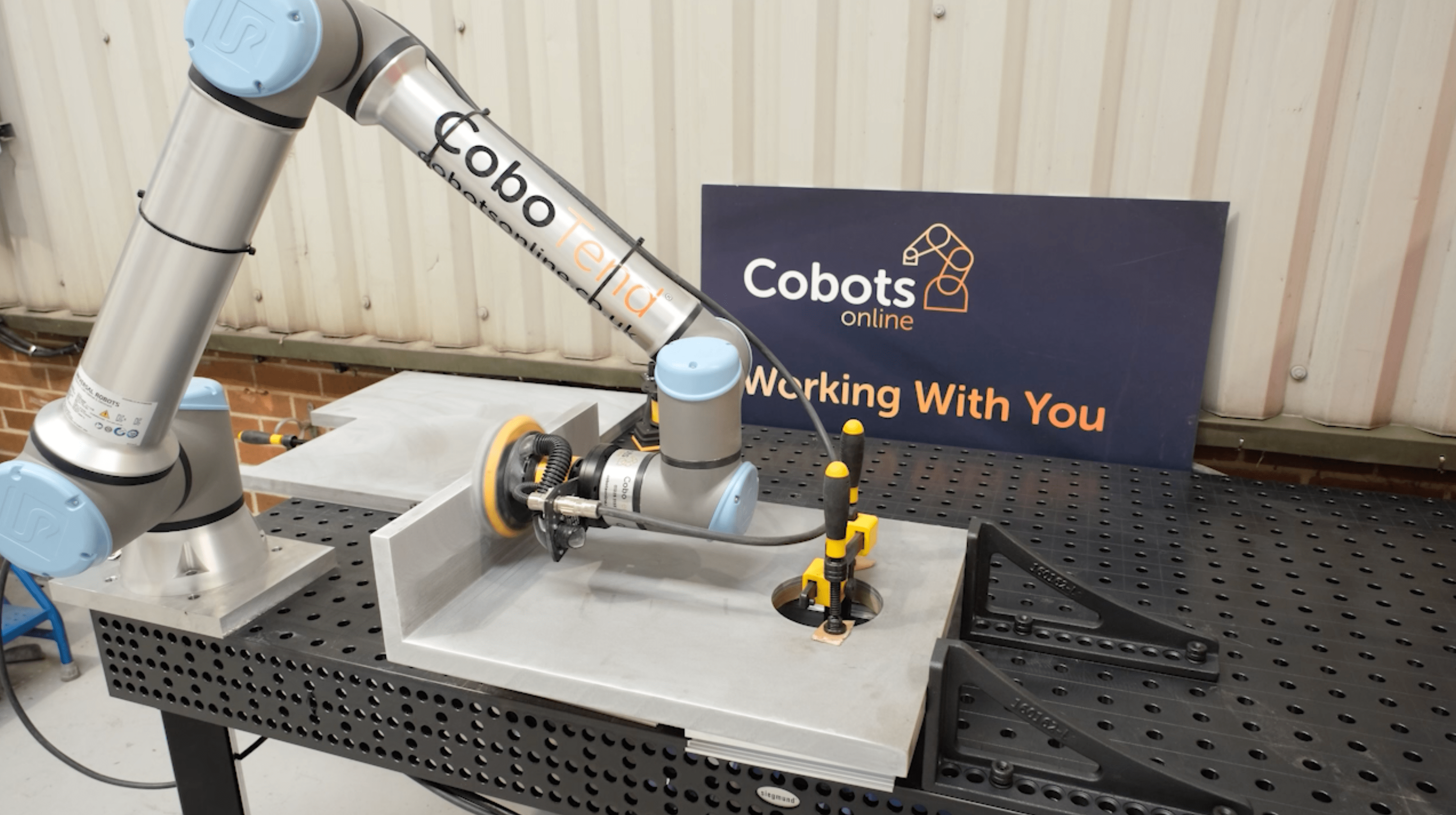

Finishing

The incredibly monotonous and highly repetitive task of sanding, polishing, deburring or buffing surfaces are difficult for humans to perform for extended periods of time, and with the same level of concentration. This can potentially lead to quality issues with the final project.

Automating finishing tasks ensures the same amount of force is continuously applied to a surface to deliver consistent quality. Thanks to cobots, like CoboSand, having built in sensor technology, they ensure high levels of accuracy so that the contour is followed accurately every time without deviation.

Expand your production with Cobots Online

With cobots providing a range of automation solutions, there is no better time to implement them into your processes.

Contact Cobots Online today for a demonstration of all our cobots or to discuss how cobots can work for you.